The best nails for Cedar - Shingles, Siding, Fencing, Cladding and Fascia.

When it comes to timber construction, we all know that cedar is one of the more superior materials to use. Cedar thrives in humid environments, which enables it to endure a variety of conditions. Specifically, it's superb for exterior siding as even in the face of extreme climatic fluctuations, it resists warping, swelling, shrinking, and deterioration.

In addition to this, the popularity of Cedar shows no signs of slowing. As well as consistently being specified by new-build clients, the contemporary aesthetics of cedar means that cedar timber is often in demand for modernising refurbishment projects.

There's just one problem... Whether you're a DIYer making a simple gate, or a roofing contractor fixing metres of cedar shingles, the nails that you use have the power to make or break your project. Using the correct fasteners will ensure the longevity of your hard-work and significantly reduce the chances of you having to redo it later on. So, what type of nail should you use when working with Cedar Wood?

The Correct Nails to use on Cedar

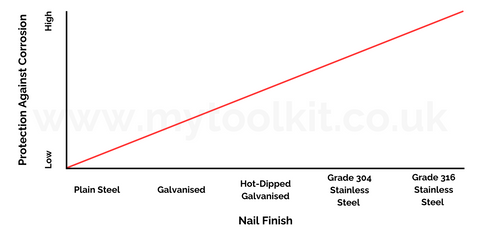

When working with Cedar wood, you should strive to use corrosion-resistant Stainless Steel Fasteners. This is because plain finish nails react with the natural oils in cedar causing them to oxidate (rust and disintegrate). Hot Dipped Galvanised nails provide some resistance but are only available in a small selection of lengths so it is unlikely to find a suitably sized nail. We'd also advise against using galvanised fasteners on any cedar wood project as they aren't satisfactorily protected against corrosion.

Other Fastener Options for Cedar

As with most things, there is never a one size fits all and although we specialise in collated staples & nails, it is important for us to be transparent so that you have all the information you need to make an informed decision. Collated nails aren't the only fastener you can use when working with Cedar, you may consider loose screws or nails - with a stainless-steel finish of course. Let us explore your options...

Collated Nails

There are two main collation styles that we'd recommend for fixing cedar, wire collated coil nails and plastic collated strip nails. Both of these options are first-fix nail types so they're very capable of holding without the need for adhesives or any other second fixing. Key considerations to make before deciding which is best suited to you include their shank type, Tip style, diameter, length, corresponding tool required and of course, price.

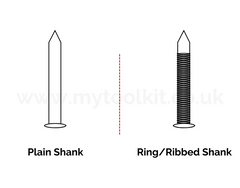

Shank

Plastic collated strip nails: Ring (Ribbed) shank and Plain (Smooth) shank

Wire collated coil nails: Ring (Ribbed) shank

Put simply, ring (or ribbed) shank nails provide greater holding power over Plain (or smooth) shank nails.

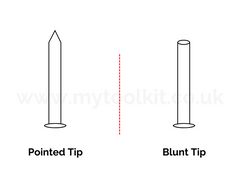

Tip

Plastic collated strip nails: Pointed tip

Wire collated coil nails: Pointed and Blunt tip

The more common tip type is pointed but we'd recommend blunt nails for fencing as they're less likely to split wood. You can see an explanation of why here.

Diameter

Plastic collated strip nails: 2.8 - 3.1 dia.

Wire collated coil nails: 2.1 dia.

While it's only a concern if the cedar is thin, larger diameter nails provide greater holding power but equally increase chance of the cedar splitting. The key consideration here should be aesthetics - would you like the visible head of the nail to be larger or smaller?

Length

Plastic collated strip nails: 50-90mm

Wire collated coil nails: 32-50mm

You'll know what length nail you need based on the thickness of your cedar and the material you're fixing to, but as a general rule of thumb, you should aim for your nail length to be 2x the thickness of your cedar (without the point poking through the other side).

Tools

Plastic collated strip nails: Gas, Battery & Pneumatic

Wire collated coil nails: Pneumatic

Plastic collated strip nails are the favourable here as they'll work with the popular Paslode IM350 gas nailer, DeWalt battery nailers and pneumatic strip nailers. On the other hand, tools for Stainless Steel coil nails are only manufactured as pneumatic. Of course, pneumatic tools offer a superior firing power but gas and battery nailers are often considered as more convenient, just remember to include the cost of gas canisters in your calculations.

Price

Plastic collated strip nails: £59.34/k +VAT (50mm)

Wire collated coil nails: £23.81/k +VAT (50mm)

Of course it's very difficult to directly compare these nails against each other on price due to the vast variations, however this might give you some indication. Based on 2.8/50mm Ring Shank Stainless Steel Strip Nails and 2.1/50mm Ring Shank Stainless Steel Coil Nails, the cheaper option (per 1,000 nails) are the coil nails. Having said that, they're sold in much larger quantities. The example coil nails we're comparing here come in boxes of 11.2k (£266.67 +VAT initial outlay) whereas the strip nails are sold in boxes of 1k. It would be important to consider how many nails you expect to use and how much of an initial outlay that warrants.

Loose Screws

As we mentioned earlier, we're by no means experts in the field of loose fasteners, but is important that you're fully informed of your options. Providing that they're stainless steel, you won't have any corrosion issues when using screws to fix your cedar. That said, some key considerations that we're aware of include...

- Screw Colour: Black, Gold or Silver (plain)

- Screw Head: Cylinder or Flat.

- Screw Diameter: 4.5 - 6.0

- Screw Length: 50-100mm

- Screw Thread Length: Full shaft or Partial shaft

We recommend liaising with your local timber merchant for more information related to the best screws to use on cedar wood.

Loose Nails

The key elements for consideration when weighing up the use of loose nails are very similar to that of collated nails which we explored earlier. To summarise, you should research the ideal length, shank, diameter and tip of the nail, of course not forgetting to compare the prices of each against yours or your clients budget and aesthetic preferences.

One of the most prominent downsides of choosing to use loose fasteners is the time taken to erect. Manually hammering loose nails or even drilling screws is simply no where near as time efficient as using a dedicated stapling or nailing tool. So, perhaps if you're a DIYer, loose fastenings would be more cost effective but, if you're a contractor, investing in a dedicated stapler or nailer will save you money in the long-term. Time is money after all.

As always, before making any decision, you should check and confirm continued availability of you chosen fastenings. The last thing you want is to start a project with one fastener then need to move onto another if you're supplier cannot reliably meet your demand.

Concluding Remarks

So, there we have it, the best fasteners to use on Cedar Wood. Hopefully that has helped you decide which fastener type you're going to use on your next Cedar project.

Remember, as long as it's Stainless Steel and corrosion resistant, you won't have any problems with it reacting to the natural oils of Cedar. If you'd like to learn more about why nails bleed, click here to read our article on "Stainless Steel Nails: how to stop Fence Bleeding".

Happy nailing!

If you're still confused or have any further questions, don't hesitate to get in touch. You can reach us on 0333 8000 345, info@mytoolkit.co.uk or DM us on our social media channels @mytoolkitonline.

P.s., Subscribe to our newsletter & get useful hints, tips & tricks directly to your inbox!

** When using nails, staples or any tooling equipment, it's important to follow safety guidelines and use them responsibly.